The daily production of masks is over 100 million, why is it still in the shortage?

Since the outbreak of the COVID-19, face masks have been a heated topic. How to get masks has become a problem for many people. In early February, China’s daily production of masks was more than 10 million. Till March, China’s National Development and Reform Commission announced that the daily production of masks exceeded 100 million. It only took a month for the face masks to raise from 10 million to more than 100 million, which conforted the anxiety of consumers a lot.

The increase of production cannot be separated from the race against time in all over China. Shandong Province adopted a “one-to-one” method focusing on production, improving production capacity, and ensuring operation to help companies expand production. Shenzhen has accelerated the transformation of “export to domestic sales”. The masks that were originally used for export will be sold in China immediately after registration and filing by the market supervision department with a Chinese label. As of March 2, there were 339 mask enterprises in guangdong province, with the production of masks soaring from less than 100,000 a day to more than 20 million a day.

It is not easy to walk out of such a “growth line” in such a short time. Since the outbreak of the COVID-19, the national development and reform commission has given priority to ensuring the demand of mask enterprises for labor, capital, logistics and supply of key raw materials and auxiliary materials. Facing with the huge demand, sinopec, petrochina, foxconn, byd and many other enterprises have also “cross-border”. Taking advantage of its own raw material production, sinopec will invest about 200 million yuan to build 10 production lines of Melt-blown fabric, which can be used to produce 3.6 million N95 masks or 18 million medical masks.

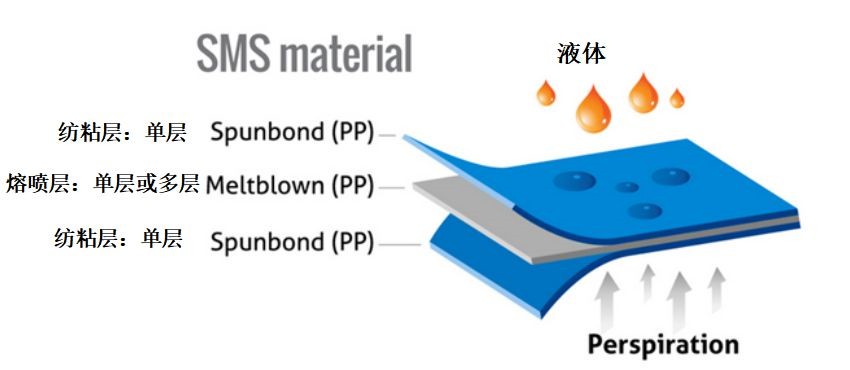

Although it is in the rapidest pace of the whip, face masks is still in a shortage, the biggest problem is Melt-blown fabric. which is one of the core raw materials and known as the “heart” of surgical masks and N95 masks. The sudden epidemic has made the Melt-blown fabric become the focus. The data shows that the average price of the Melt-blown fabric is about 20,000 yuan / ton. Since the epidemic, the price of Melt-blown fabric has even soared up to 300,000 yuan / ton!

It is reported that Melt-blown material is the raw material of Melt-blown fabric, which is a modified polypropylene product. According to JLC, the total domestic polypropylene production in 2019 will reach 26.32 million tons per year. It is in the sufficient supply. However, there are only about 10 modified companies in China that can mass produce meltblown materials. The overall production capacity is very limited.

“However, from the perspective of the polypropylene meltblown material market, Sinopec has joined the industry, Yanshan Petrochemical Company, Shanghai Petrochemical Company and private enterprise Oriental Energy are also producing meltblown materials. The supply shows positive trend.” As a whole, polypropylene meltblown material is able to support the production needs of Melt-blown fabric.

GBI Consulting Company is devoted to studying the supply chain of China raw material and face mask, to offer a complete solution of the face mask from the product sourcing, price negotiation ,factory audit ,QC ,legal support and after service. We protect you away from the virus and influenza, keep your business and families pleasure from the begining to the end. We are ready to open our supply chain to all of the clients to help you make a growth of your business, get in touch with us to start a profitable business NOW!