Witness the modernization: The integration of 3D printing with the medical industry

As 3D printing technology becomes much more mature, the applications in various industries are gradually emerging. At present, the main applications of 3D printing in the medical industry include, 3D printed medical models for surgery planning and teaching, surgical stents, surgical and oral implants, rehabilitation equipment, and 3D printed biological human tissues and organs. Materials are upgraded day by day, and biocompatible 3D printing materials have created practical cases for the clinical application of 3D printing blood vessels and organs.

-

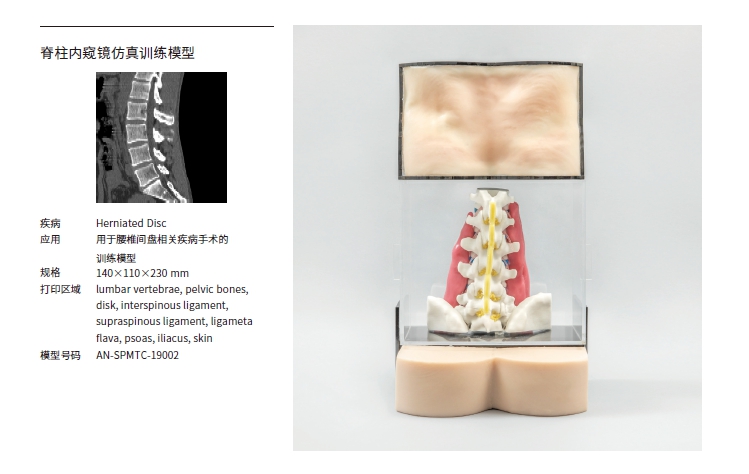

3D printing of medical models and surgical guides

The use of 3D printing can provide hospitals with a more intuitive and clear model of the surgical site structure. First, it is necessary to perform 3D modeling based on the patient’s CT data before surgery, and then use a 3D printer to print out the model to obtain a medical model. This model helps doctors make surgical plans, especially for these complex operations, which can reduce surgical risks and increase the success rate of operations.

-

3D printing of rehabilitation equipment

3D printing can accurately customize rehabilitation equipment such as orthopedic insoles, bionic hands, hearing aids, etc., the efficient digital manufacturing technology used to replace manual production methods can shorten the production cycle. Taking hearing aids as an example, using traditional techniques to make an injection mold from the ear canal model of the patient, the technician needs to perform post-processing such as drilling sound holes on the mold. And to make a hearing aid with a 3D printer, what to do is simply turn the scanned CAD file into a design file that a 3D printer can read and print it out. In addition to industrial applications, the large industrial 3D printers currently can also be used for medical model printing. The SLA 3D printer of Xunshi Technology has a large printing format and can print 48 hearing aid models per hour.

-

3D printing of implants for surgery

The diseases like bone defects, maxillofacial injuries, and skulls injured caused by bone tumors, car accidents, etc. cannot be treated with general repair products. 3D printing products provide effective solutions. The printed prosthesis can be customized according to the patient’s characteristics.

At present, digital dental technology is precisely using 3D printing technology for dental treatment. Digital guides can make dental medical treatment more accurate, and can effectively alleviate the problem of shortage of dental medical resources.

-

3D printing of pharmaceutical

The main impacts of 3D printing technology on drug manufacturing include: to achieve personalized customization of active ingredients of drugs, to personalized customization of dosages to personalized customization of shapes, and to enable drugs to have a special microstructure, improving drug release behavior, and reducing efficacy Drug side effects.

-

3D printing of organ

Organ 3D printing has already been successfully applied. In April 2019, Tel Aviv University in Israel successfully printed the world’s first intact heart with cells, blood vessels, ventricles, and atria, though the patient’s tissues as raw materials.

As an emerging technology of printing consumables, 3D printing has achieved initial popularity. But there are still some difficulties in clinical application in the medical industry. Breaking the limitations of materials is the key to a better combination of 3D printing and the medical industry in the future. It is foreseeable that precise digitization must be the future development direction of the medical industry. Especially in China, where medical resources are still in short supply relative to the national population, the popularization of 3D printing technology is the general trend.