Environmental protection | Why we choose bagasse and bamboo fiber?

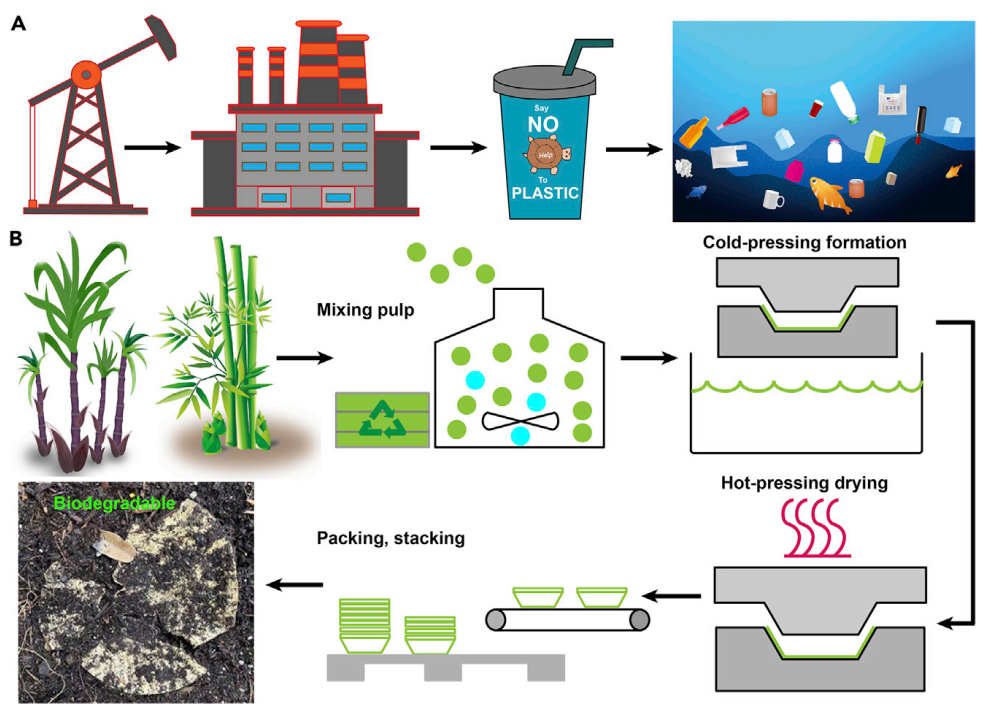

In the past few decades, synthetic plastics, which were used for food packaging, have been widely used worldwide. Most of them are not biodegradable, brought about serious environmental issues. Now, the increasing development of environmental protection concepts and technology has pushed people to pay more attention to sustainability. Replacing plastics becomes an urgent need, which spawned one of the degradable and environmentally friendly materials – bagasse and bamboo fiber.

Previously, bagasse was useless. But when it meets modern technology, it may exceed our imagination: to produce fuel alcohol, feed, reuse as an environmentally friendly material, extract polyphenols, and so on. Bagasse is the residue of sugarcane after squeezing. The dry matter content in bagasse is high, among which cellulose accounts for 42%-50% -the length of the fiber is about 0.65-2.17mm, and the width is 21-28μm. In other words, the fiber form of bagasse can be comparable to wood and bamboo, and can be a notch above rice and wheat straw fibers!

In addition, it is neither soluble in water nor organic solvents. It will not melt when heated. When meeting high temperature or acidic conditions, It can be decomposed, and hydrolyze. It means that bagasse products are very environmentally friendly while maintaining availability.

Another environmentally friendly material, bamboo fiber, is also a recycled fiber made by extracting cellulose from bamboo with glue and spinning.

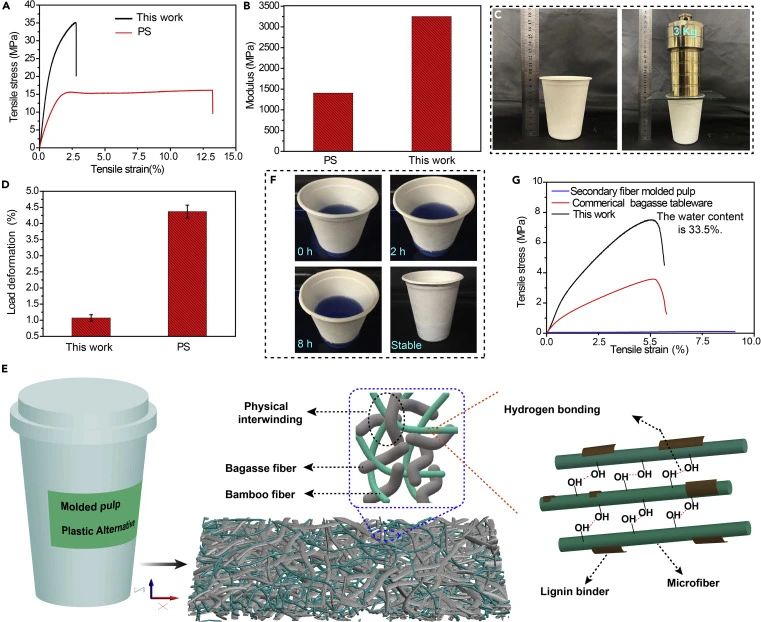

The two fibers can be blended and entangled to form an interwoven network structure. And the disposable tableware prepared by the cold pressing and hot pressing drying process is able to completely replace traditional plastic paper.

To further confirm, some scholars did the research and the results proved that the content of toxic substances in the pulp molded tableware is lower than the international standard. Also, the food-safe AKD grafted pulp fiber and precision molding process improved the hydrophobicity and hydrogen bonding between the fibers. At the same time, the carbon dioxide emissions in the production of pulp molded tableware are lower than the carbon dioxide emissions of PS plastic products and traditional papermaking. A series of studies show that: The pulp molded tableware synthesized from bagasse and bamboo fiber is a biodegradable, low-cost, high-strength tableware!

A series of plant fiber replacement materials represented by bagasse and bamboo fiber are developing in the direction of environmental protection.

As the “world factory”, China has long since joined in environmental protection and plastic bans. Countless Chinese manufacturers use bagasse as raw material to produce disposable environmentally friendly tableware. It requires the quality of raw materials and professional techniques such as pulping and film-forming, so the quality difference levels are uneven.

Now GBI creates opportunities and value for you, not only in the environmental protection business. We help you in product sourcing, price negotiation, factory audit, QC, legal support, and after service. Since the outbreak of the COVID-19, GBI has successfully helped more than 50 countries import. Making you more resilient in the global value chain and protect your business and family from beginning to end is what we are doing. Get in touch with us to start a profitable business NOW!