Global container shortage drives spike in shipping rates. Why did it happen?

It has to dates back to the blockage of the Suez Canal in March. In March 2021, the Suez Canal was blocked for six days after the grounding of Ever Given, a 20,000 TEU container ship. The 400-meter-long (1,300 ft) vessel was buffeted by strong winds on the morning of 23 March and ended up wedged across the waterway with its bow and stern stuck in the canal banks, blocking all traffic until it could be freed. The obstruction occurred south of the section of the canal that had two channels, so there was no way for other ships to bypass Ever Given.

As one of the world’s busiest trade routes, the canal obstruction had a significant negative impact on trade between Europe and Asia, and the Middle East.

On 28 March, at least 369 ships were queuing to pass through the canal. This prevented an estimated US$9.6 billion worth of trade.

And the congestion of the Suez Canal in March kept the shortage of container supplies still in place. Lately till to May, global foreign trade companies have once again faced a lack of space and containers. The difficulty is comparable to the scene of the “Chinese Spring Festival travel season”. Billions of people were rush for booking & transporting.

For the situation in the US now, there are more than 30 container ships waiting at the Port of Los Angeles and Long Beach the United States. 85% of the ships need to anchor for at least 8 days before they are able to operate. The container cargo can stay at the terminal for up to 2 months.

And for European routes, ships generally call at multiple ports. Due to congestion in the main ports of call, the entire sailing time is lengthened.

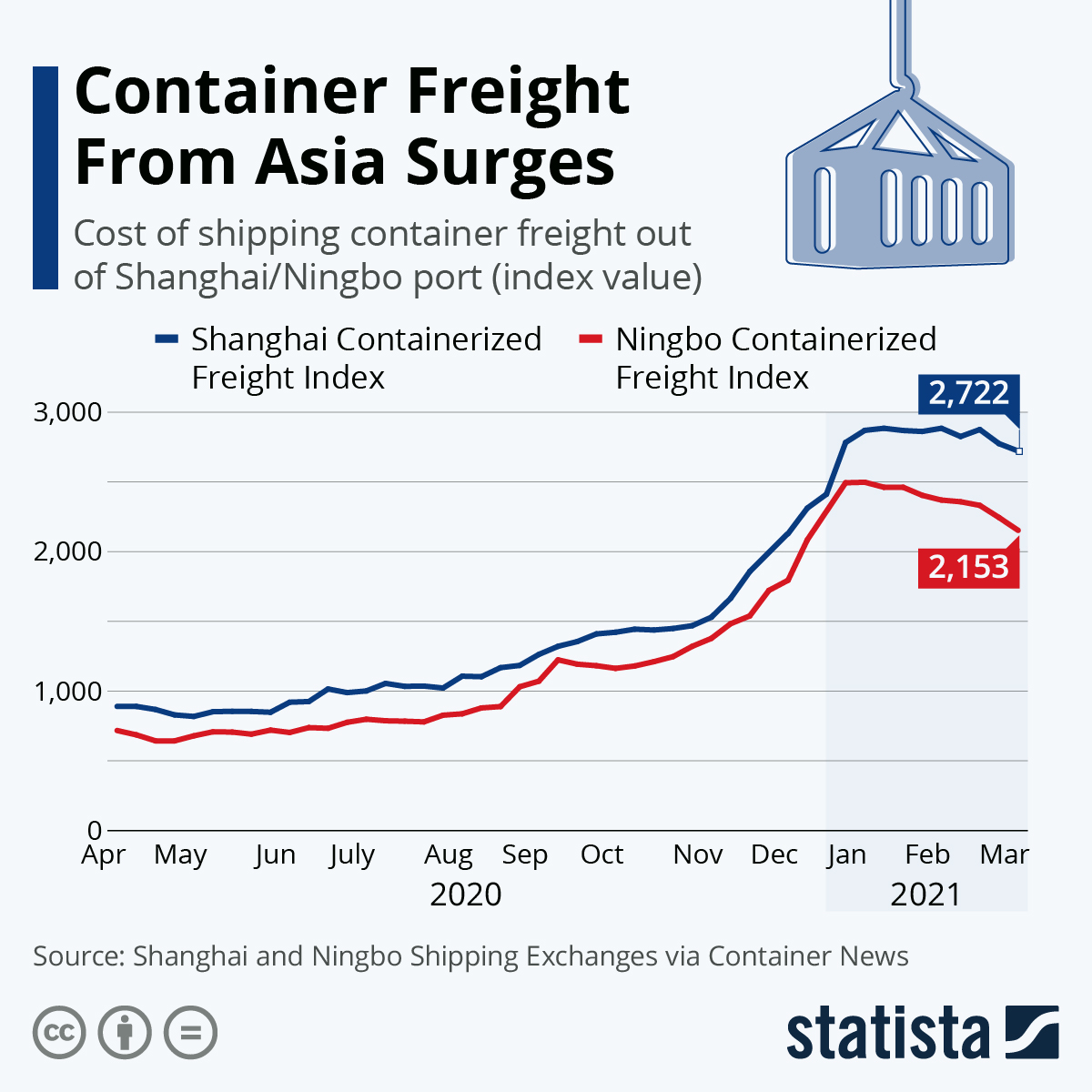

The data shows that among the major ports along the Maritime Silk Road, 12 ports have increased their freight index. The high freight rate is mainly due to the stable situation of the epidemic in China. A large number of overseas orders rushing into China, and the lack of capacity in the main routes, which eventually led to a large backlog of products in many domestic foreign trade companies.

The current ship’s tight capacity, shortage of empty containers, and rising freight rates have become a global problem. Not only China, but also Vietnam, India, and South Korea witness rapid increases in freight rates, and some major routes have even exceeded Chinese freight rates.

From the perspective of demand, China recovered quickly from the covid-pandemic , and the intensity of imports from China has also sharply risen. The large amount of demand led to insufficient capacity and increase of the freight rates. As a result, China container ships out of the country are always full load, but when they return, they are empty.

From the perspective of supply, when the freight rate reaches a certain level, the market economy will be regulated by the government, as a result, the number of ships and crews will be increased. This is also relying on increasing supply to achieve a balance between supply and demand.

So in the short term, freight may be a problem, but it may not last for long. Why? Because the invisible hand of the market, it will of course stabilize the market prices, and restore the balance between supply and demand.

The impact of freight is all over the world, but this storm is not inevitable. GBI provides you with the most efficient and economical shipping method. While avoiding the loss of rising freight rates, we provide you with the safest, most efficient and cost-saving service. GBI helps you in product sourcing, price negotiation, factory audit, QC, legal support, and after-service. Making you more resilient in the global value chain and protect your business and family from beginning to end is what we are doing. Get in touch with us to start a profitable business NOW!